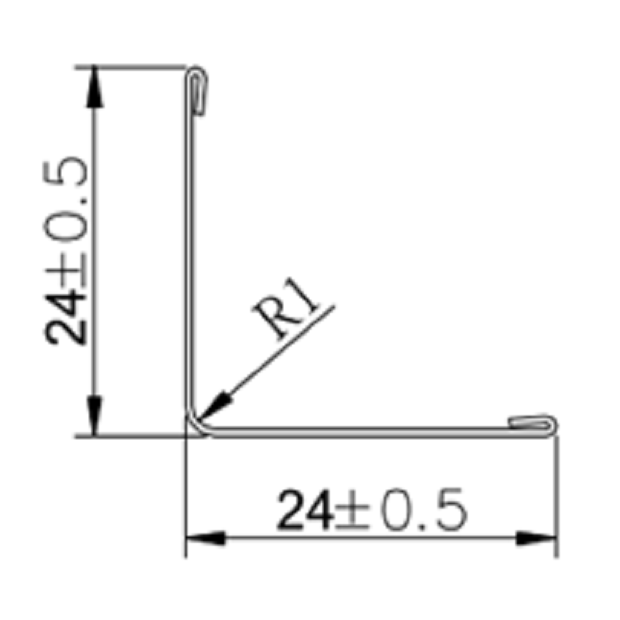

| Raw material | Pre-painted or galvanized steel Strip thickness: 0.4-0.45mm |

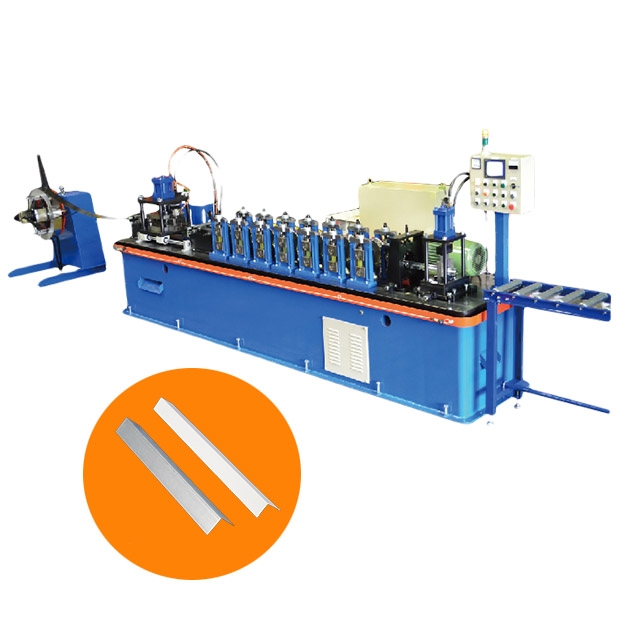

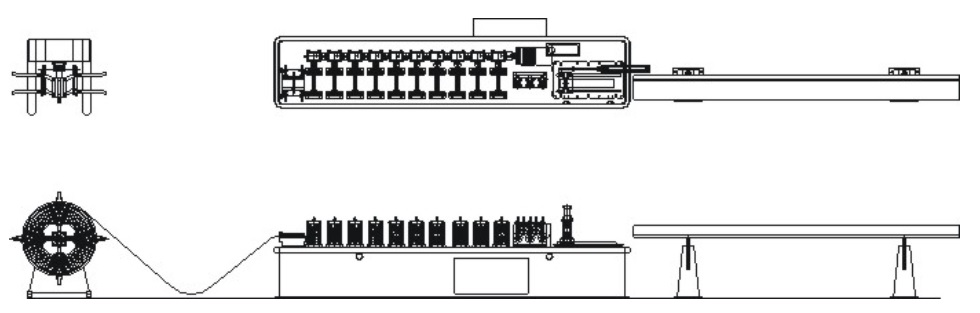

| Machine Layout |  |

| Process | Coil → Profile Roll forming → hydraulic cut-off after forming → Finished products. |

| Features | 1.Automatic manufacturing process. 2. Forming speed: Max 25-30Meters/minute. Forming speed is adjustable. 3. Automatic hydraulic cut-off device. 4. Cut-off blade material is in alloy SKD11, vacuum heat treated, Hardness is HRC 58-61°, wear-resistant, rigid structure and durable. 5. Product length : 1M ~ 3.0M (or more), length is adjustable. 6. Length tolerance within ±3.0mm. |

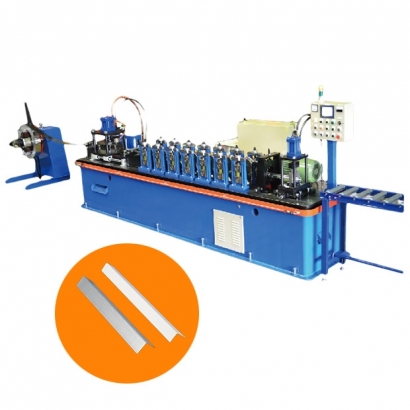

| Specification | A. Uncoiler x one unit. 1. Loading capacity : 1,100 Kgs 2. Coil specification : O.D.: 1,200 mm. / I.D.:480 – 510 mm. Strip width : 100 mm. 3. Manual coil tightening 4. Driven by forming machine. B. Cold roll forming machine x one unit. 1. Model: G-240-CL type. (Changeable type) 2. Roll Forming Stands: 10 stands with entry guide stand. 3. The machine base is made of high-strength steel with precise welding, stress relief treatment. Each stand will have an individual worm gear reduction, and common drive shaft to make all rollers are running simultaneously. 4. Main driven motor: 7.5 HP motor with 7.5HP inverter. 5. Forming rollers: one full set. 6. Roll shaft: Ø40mm, in S45C material. 7. Rolls: use the material SKD11 with vacuum heat treatment, Hardness is HRC 58-61, wear-resistant and durable. C. Hydraulic automatic cut-off device x one unit 1. Cut-off blade is in material of SKD11 with vacuum heat treatment, Hardness HRC 58 – 61, wear-resistant, steel structure, long life. 2. Unique design gives trouble-free operation. 3. Cut-off length: 1M – 4.0M, Length is adjustable. Length tolerance within ±3.0mm. 4. Hydraulic pack (3 HP): 1 set. 5. Cut-off blade: 3 sets. D. Product run-out table (3.5 Meter) x one unit. Material run-out table for finished parts collection. E. PLC electric control system x one unit. 1. Mitsubishi PLC controller x 1 set 2. HMI control panel x 1 set. 3. Electric voltage will be confirmed before placing order. |

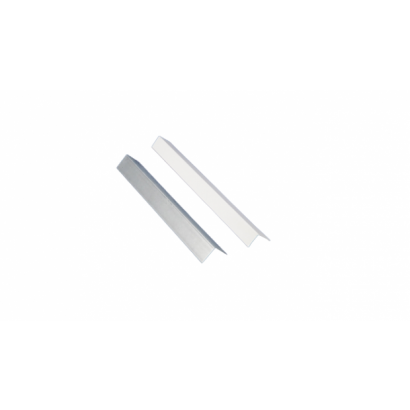

Wall angle

Automatic Wall Angles Cold Roll Forming Machine

Automatic Wall Angles Cold Roll Forming Machine

Cold roll forming machine for Making Wall Angles.

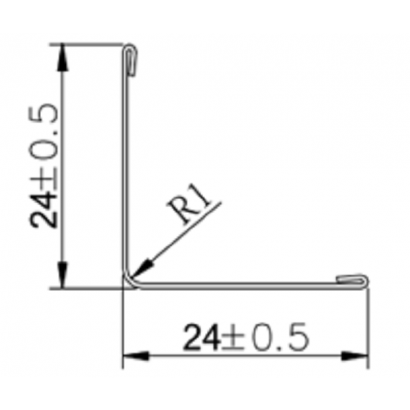

DETAIL