| Raw Material | High tensile galvanized steel G350-G550 Strip thickness: 0.8-1.5mm Inspection standard: G350, 1.0mm |

|

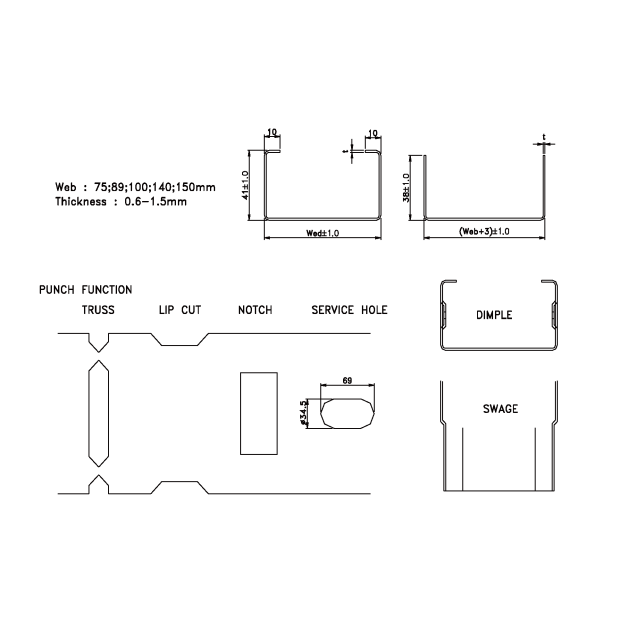

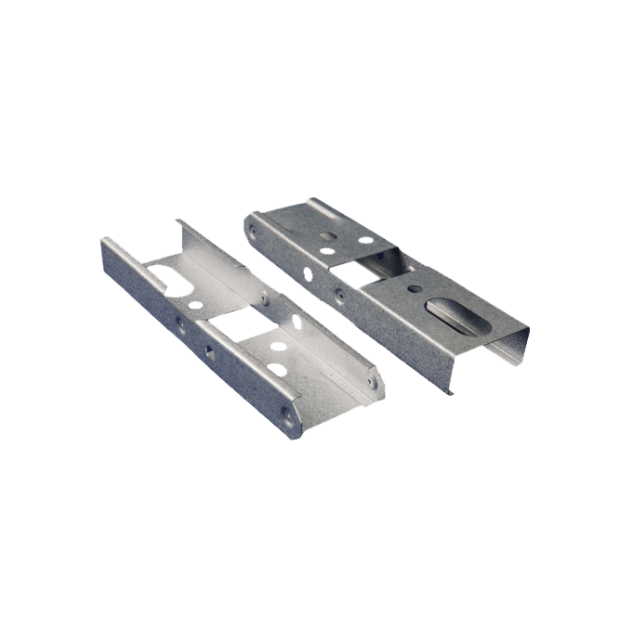

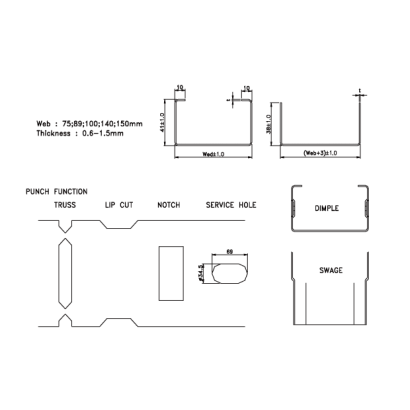

| Profile | Single Web Size Profile (C+C & C+U) Framing System | |

| C – Profile | U - Profile | |

| A1-75 (75x41mm) or A1-89(89x41mm) or A1-100(100x41mm) or A1-140(140x41mm) or A1-150(150x41mm) |

A1-75 (78x38mm) or A1-89(92x38mm) or A1-100(103x38mm) or A1-140(143x38mm) or A1-150(153x38mm) |

|

| Machining Process | Coil →Entry guide→ Punching die sets (Truss, notch, lip cut, service hole) → Roll forming →Punching die sets (dimple, swag) → Crimp and shear→ Finished products. |

|

| Punching Features | Service Hole, Web Notch, Lip cut, Truss, Dimple, Swage, Crimp, Shear.jpg) |

|

| Features | 1. Fully automatic continue production, max thickness up to 1.5mm 2. Forming roller transmitting system: Driven by servo motor, individual reduction gear for each forming stand. All rollers are turning simultaneously. 3. Max roll forming speed: 30M/minute (or 1800M/hour). 4. Control system: CNC Control. 5. Forming rollers and punching dies are in alloy steel SKD11, vacuum heat treatment, Hardness up to HRC 60°, wear-resistance, and durable. |

|

| Specification | A. Automatic Single Head Uncoiler x 1 Unit 1. Loading capacity: 2,200 Kgs 2. Coil specification: - O.D. 1,300 mm. - I.D. 480 – 510 mm. - Material width : 250 mm 3. Manual coil change and tighten 4. Driven by 2 HP motor B. Entry & Lubricate system x 1 Unit 1. Lubrication system: 1 set 2. Entry guide with the counter wheel: 1 set C. Punching die sets x 1 Unit 1. Punch before roll forming section, a. Truss (75/89/140), b. Notch (75/89/140), c. Lip cut (75/89/140) , d. Service hole and index hole 2. After roll forming section, a. Dimple, b. swage, c. Crimp & Shear (75/89/140) 3. Punching dies are in alloy steel SKD11, vacuum heat treatment, Hardness up to HRC 58-61°, wear-resistance, good rigid structure and durable. D. Cold roll forming section x 1 Unit 1. Forming station: 7 ~ 8 stations 2. Driving motor: 7.5KW servo motor 3. Forming rollers: one full set for 89 mm. 4. Roller shaft: φ50mm, mild steel, heat treated and grinding. 5. Rollers: Alloy steel SKD11, vacuum heat treatment, hardness up to HRC 58 ~ 61°, wear-resistance, rigid structure and durable. 6. Hitachi industrial printer: 1 set E. Hydraulic system x 1 Unit 1. Hydraulic motor: 7.5HP with 3.0Liter accumulator. 2. Fan type oil cooling system: 1set F. Run out table (4.5M) x 1 Unit G. Computer control system x 1 Unit 1. CNC controller: 1 set 2. IPC with Win 7 PRO and control software x 1 set 3. 17” touch screen x 1set 4. Input power: will be specified. 5. Controller power: DC24V/Ac220V H. Vertex BD Pro Design software x 1 license copy 1. The Design software can make C+C & C+U design. 2. The Design software with 2D and 3D function. 3. The CAD can be transmitted into CAM file for manufacturing. |

|

Roll Former A1

Automatic Light Gauge Steel Frame Cold Roll Forming Machine in Single Size

Automatic Light Gauge Steel Frame Cold Roll Forming Machine in Single Size

Cold Roll Forming Machine for making Light Gauge Steel Frame A1 X-89

DETAIL