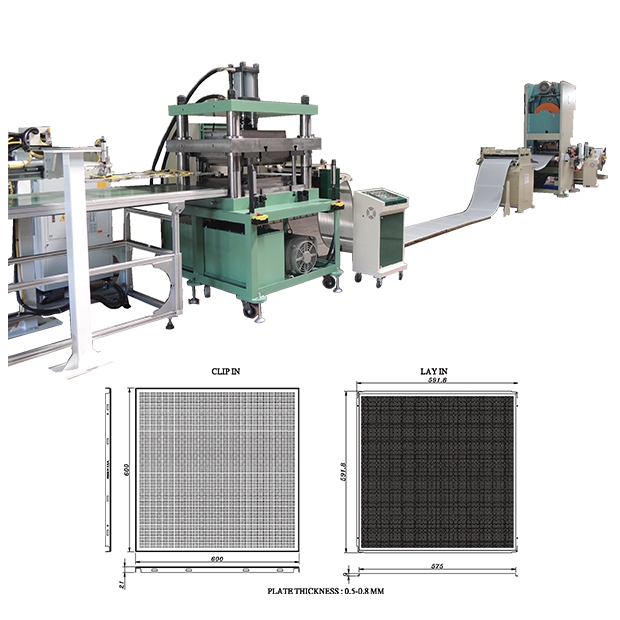

| Raw Material | Aluminum coil Strip thickness : 0.5-0.8mm |

| Process | Coil (Uncoiler) → Leveler → NC Feeder → Press (dies)→ Leveler → NC Feeder → Hydraulic Press (dies)→Robot→ Conveyor→ Finished products. |

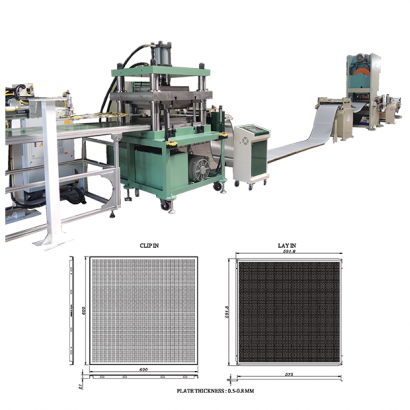

| Specification | A. Single head Uncoiler x one unit. 1. Loading capacity: 3.000 Kgs 2. Coil size: O.D. 1,200 mm. I.D. 480 – 510 mm. Width: 700 mm. 3. Manual coil tightening 4. Driven by leveler B. Leveler x one unit 1. Strip thickness: 0.8mm. 2. Max. strip width: 700mm. 3. Driven by motor and sensor C. NC Feeder x one unit 1. Plate thickness: 0.8mm. 2. Max. plate width: 700mm. 3. Feeding length: 30mm per pitch. 4. Controlled by press. D. Press x one unit 1. Capacity: 110 Tons. 2. Max. speed: 50 strokes/minute. 3. Controlled by sensor. 4. Pressing dies: Holes punching and notch die set (for Lay in): one set Holes punching and notch die set (for Clip in): one set E. NC Feeder x one unit 1. Plate thickness: 0.8mm. 2. Max. plate width: 700mm. 3. Feeding length: 700mm per time. 4. Controlled by press. F. Hydraulic Press x one unit 1. Capacity: 30 Tons. 2. Max. speed: 3 strokes per min. 3. Controlled by sensor. 4. forming and cut off dies: Forming and cut off die set for Lay in: one set Forming and cut off die set for Clip in: one set G. Robot and conveyor x one unit. 1. Feature: Pick up the product from the conveyor H. PLC electric control system x one unit. 1. Programmable controller: 1 set. 2. HMI control panel: 1 set. (Touch screen type) 3. Electric voltage will be confirmed before placing order. |

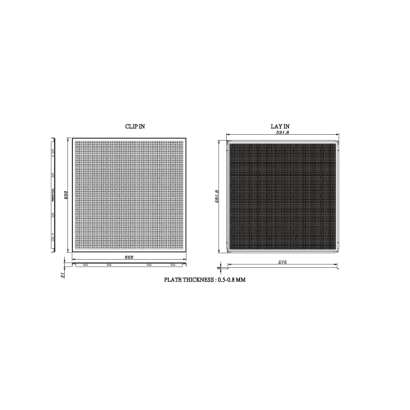

Ceiling Tile

Aluminum Lay in/ Clip in Ceiling tile Making machine.

Aluminum Lay in/ Clip in Ceiling tile Making machine.

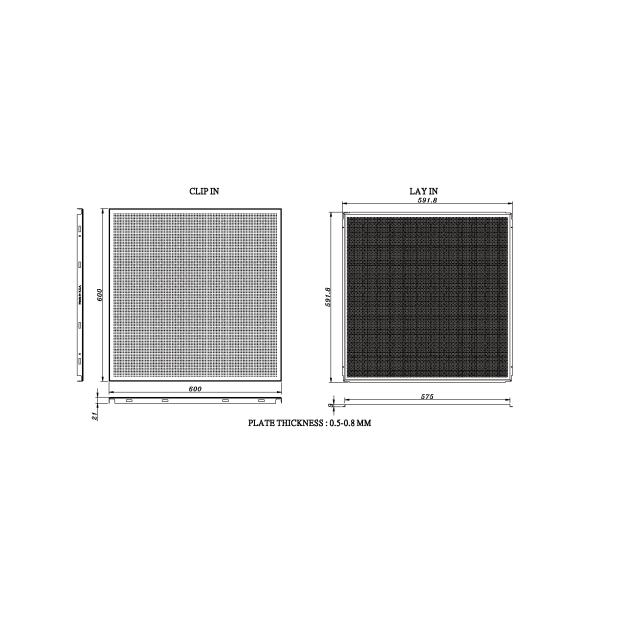

Aluminum Lay in/ Clip in Ceiling tile Making machine.

DETAIL