| Raw material | Galvanized steel, Plate thickness: 0.4-1.0mm |

| Process | Coil →Roll forming → Automatic punching & cut-off after forming → Finished products. |

| Features | 1. Forming roller transmitting system: Driven by AC motor on common shaft, individual reduction gear for each roll forming stand. All rollers are turning simultaneously. 2. Forming line speed: 70M per minute or 22-24 Pieces/minute for a 3 meters length product. Roll forming speed is adjustable. 3. Automatic flying shear device: hydraulic power system, easy and long-lasting operation. Cut-off blade is in material of SKD11, vacuum heat treatment, Hardness up to HRC 58-61°, wear-resistant, rigid structure and durable. Products length: 1.5 – 3.0 meters (or longer), length can be adjusted. Length tolerance is ±3.0mm. 4. Special designed tool holder for easy cutter change. |

| Specification | A. Single head Uncoiler x one unit. 1. Loading capacity: 1,100 Kgs 2. Coil specification: O.D. 1,200 mm. I.D. 480 – 510 mm. 3. manual coil tightening. 4. driven by forming machine. B. Cold roll forming machine x one unit. 1. Model : G-280-L type. (Fixed type) 2. Forming steps : 10-11 stations with entry guide stand. 3. The main machine base is assembled by high-strength steel with precise welding treatment. Each steps with one worm gear reducer, turning simultaneously. 4. Main driven motor: 20 HP . 5. Forming rollers: one full set for Omega channel 6. Roller shaft: Ø45mm, in S45C material. 7. Rollers are in SKD11 material with vacuum heat treatment, Hardness up to HRC 58-61°, wear-resistant, rigid structure and durable. 8. Forming speed: 70 meters/ minute. Speed is adjustable. 9. Cooling system: 1/2HP pump for forming rollers x 1 set 10. Channel straightener: 1 set C. Automatic Hydraulic Flying Shear device x one unit 1. Cut-off blade use the material of SKD11 with vacuum heat treatment, Hardness up to HRC 58 – 61, wear-resistance,rigid steel structure, durability. 2. Unique design for trouble-free operation. 3. Cut-off length: 1.5 – 3.0 meters (or longer), Length is adjustable. Length tolerance is ±3.0mm. 4. Hydraulic power pack (5HP) with accumulator: 1 set. 5. Oil cooler: 1 set 6. Products cut-off blade x 1 set. 7. Servo motor: 5KW E. Product run-out table x one set Material run-out table for finished parts collection. Feature: product holding device Piling device for products X 2 sets. F. PLC electric control system x one set 1. Mitsubishi PLC controller x 1 set 2. HMI control panel x 1 set. 3. Electric voltage will be confirmed before placing order. |

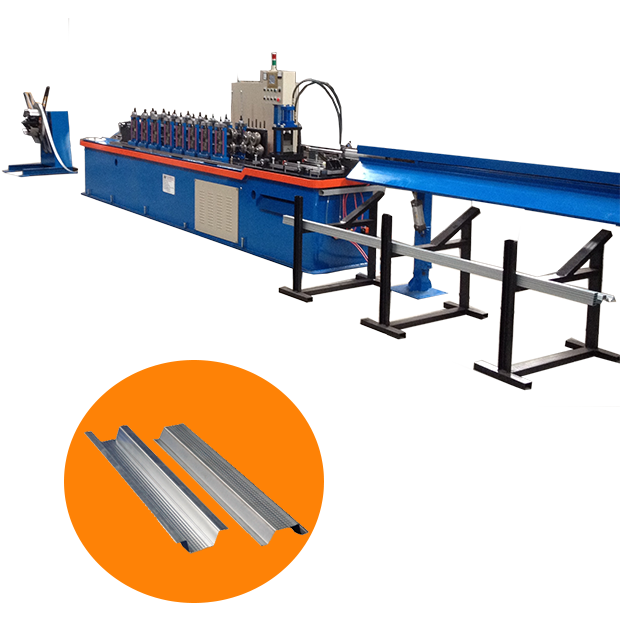

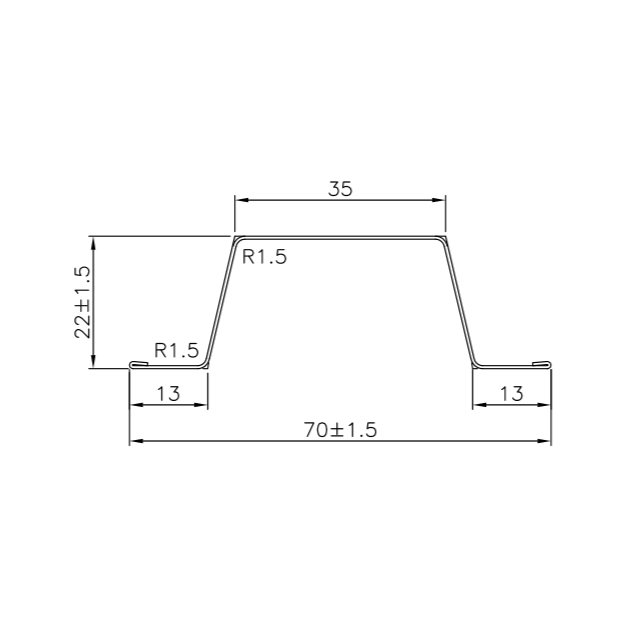

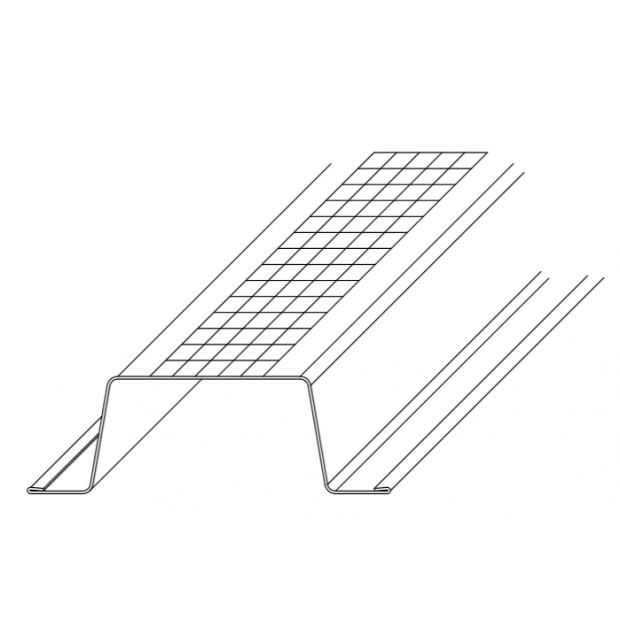

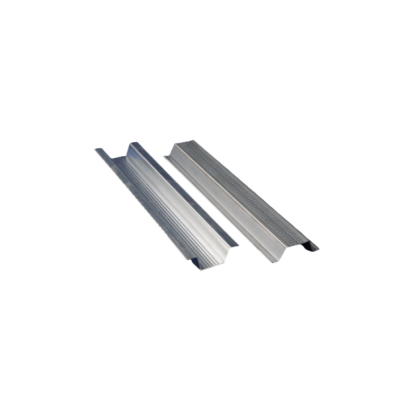

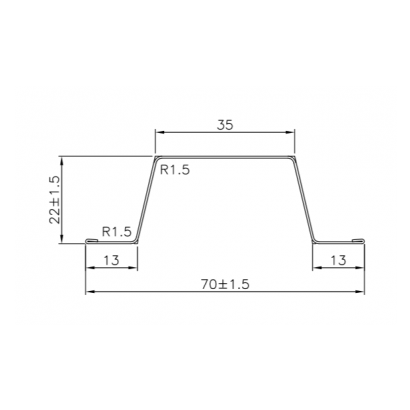

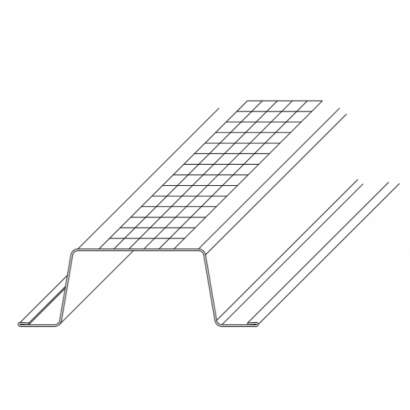

Furring Channel (Omega Channel)

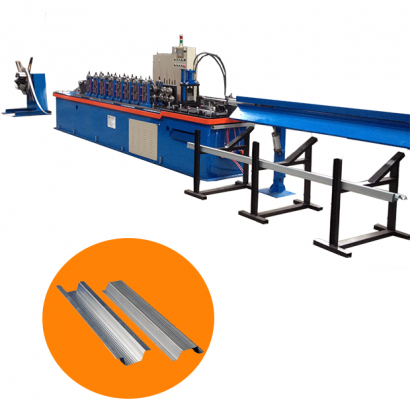

Automatic Cold roll Forming Machine for Furring Channel. Fly shearing type.

Automatic Cold roll Forming Machine for Furring Channel. Fly shearing type.

Cold Roll Forming Machine for Making Furring Channel (Omega Channel)

DETAIL